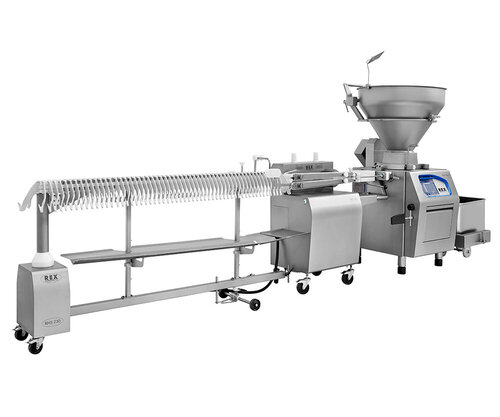

Industrial slicer

Designed for heavy duty, the operation is reduced to a minimum. The machine can be operated extremely comfortable step by step via the integrated LCD display. Clear symbols ease a fast input and gather all cutting data at a stroke.

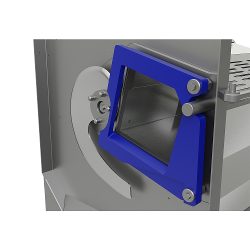

User-freindly operation due to integrated display

The integrated LCD display offers extraordinary features for the comfortable operation of this machine. The operator keyboard is made of synthetic material with single removable buttons for fast and easy cleaning. All parameters of the cutting process can easily be surveyed by clear symbols on the display.

Slicing software for the IC machines

With the slicing software you can choose from up to 5 different slice thicknesses during the slicing operation. For each of these different thicknesses the number of slices can be chosen freely.

How the software works, example of portioning

- Section Thickness 140 mm: 1 cut

- Section Thickness 25 mm: 6 cuts

- Section Thickness 20 mm: 5 cuts

- Section Thickness 23 mm: 3 cuts

- Section Thickness 100 mm: 1 cut

Productivity:

- Up to 600 slices/minute

- Short cycles due to automatic return limiter

- Start and search device

- Automatic distribution of the remaining slice (optionally available)

- Automatic flap start after closing the flap (optionally available)

- Pneumatic gripper (optionally available)

- Automatic ejector for remaining slice (optionally available)

Handling:

- Easy operation via LCD display with clear symbols

- 100 programs storable

- Highest safety standard

- Equal distribution of products according to the number of slices

- Slicing software for cutting in section

- Compartments and separation of the products

Slicing result:

- Precise result also for on the bone products due to MHS micro-toothed blade

- Adjustment of blade speed

- Exact feed due to less friction on structural surfaces

- Forward feed mode selectable, continuous or step by step

- Optimized hold of the product due to adjustable gripper (optionally available)

Versatility:

- Single cut function with higher speed of blade to increase slice quality on low production rate (optionally available)

- Outfeed conveyor belt (optionally available)

- Reverse executions (optionally available)

- Stainless steel flaps (optionally available)

- Diversification of machines in product cross section and product length (optionally available)

- Weight optimized slicing (optionally available)

Details

IC 700

Input length: 700 mmCross section: 250 x 240 mmCutting length: 0.5 mm - unbegrenztDimensions: 1925 x 950 x 1420 mmWeight: 450 KgVoltage: 400 V

IC 1100

Input length: 1100 mmCross section: 250 x 240 mmCutting length: 0.5 mm - unbegrenztDimensions: 2725 x 950 x 1420 mmWeight: 500 KgVoltage: 400 V