Never again tired and heavy arms from tapping

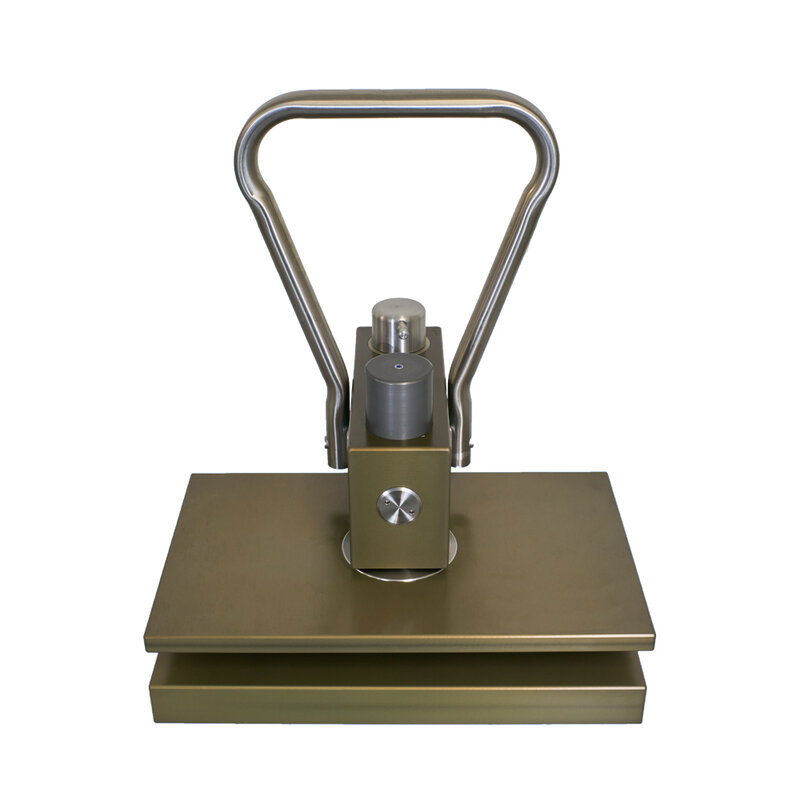

Scallop flattening and the resulting dirty workplace with blood and meat residues is a thing of the past thanks to our scallop flattener. Our manually operated carving flattener is easy and safe to use. Thanks to the unique lever mechanism developed by our engineers, you can effortlessly press the cutlets to a preset thickness in seconds and without much effort with a pressure of up to 2.5 tonnes.

No more tired and heavy arms from tapping. In constant dialogue with experts from the catering industry, we have succeeded in developing a device that can be used for continuous operation in large kitchens as well as for snack bars and bistros. The quick, infinitely variable adjustment of the pressing plate distance enables the processing of all meat sizes from cutlets to steaks.

All components that come into contact with the meat are easy to clean without disassembly.

The use of high-quality materials and well-engineered components guarantee the long-lasting use of the pulp press. The compact and high-quality design complies with the statutory accident prevention regulations.

Details

Schnitzel press Typ L

Press area: 300 x 200 mm Press force: bis 1.5 Tonnen Dimensions: 300 x 290 x 500 mm Weight: 25 kg

Schnitzel press Typ XXL

Press area: 440 x 270 mm Press force: bis 2.5 Tonnen Dimensions: 440 x 360 x 500 mm Weight: 45 kg