The all-rounder for all sizes of business

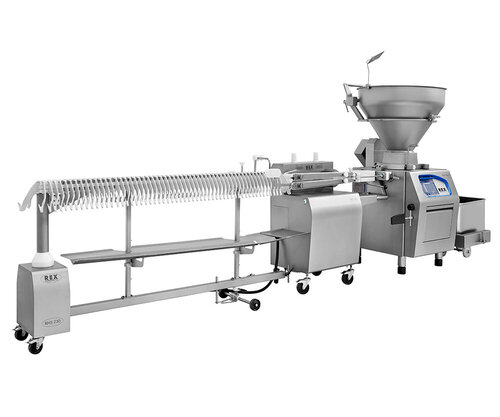

The 400 series is just as suitable for small and medium-sized meat processing companies as it is for larger, highly specialized companies. Its smooth surface, hygienically designed, space-saving machine housing, is self-supporting and made entirely of stainless steel.

The machine’s modern design allows us to fulfil the highest standards of hygiene, reducing the daily cleaning effort.

The reinforced model of the large rotary vane conveyor system guarantees highest portioning accuracy for a maximum service life. The vacuum filler does not crush or smear the product ensuring the product is transported gently throughout the filling process. The rotary vane conveyor system is available with eight, 12 or 14 vanes, alternatively also with blind vanes. A simple pressure levelling piston ensures highest portioning accuracy.

Thanks to the newly developed lifting device, the hopper of the RVF 400 - available in different sizes - can be filled simply and without any mess.

- 100 litre folding hopper

- 160 litre folding hopper

- 250 litre folding hopper

- 350 litre folding hopper

The impressive standard 12” touchscreen control makes the machine easy to operate, thanks to its large-sized control elements. Both the RVF 436 and the RVF 436 S are designed to be suitable for all applications, e.g. for operating clipping machines, REX hanging lines and attachments. The tried-and-tested "REX Servo drive" rounds off the innovative control concept. The optional case holding device makes it easy to twist artificial and natural casings.

The advantages at a glance

- Large rotary vane conveyor system for gentle transport

- Modern servo drive concept for accurate portioning

- „S“ version with servo-twisting drive

- Folding hopper variants: 100 L, 160 L, 250 L und 350 L

- Lifting/tipping device for 120- and 200-litre standard lifting trucks

- Very simple operation thanks to 12“ touchscreen control

- Einfache Bedienung durch großen 12“ Touchscreen

Details

Filling capacity

3.600 kg/h

Filling pressure

45 bar

Hopper sizes

100 / 160 / 250 / 350 Liter

Portioning and linking capacity

10 g, ca. 800 Port./min. 40 g, ca. 350 Port./min. 100 g, ca. 300 Port./min. 200g, ca. 200 Port./min.

Lifting- tilting device

120 / 200 Liter

Connecting power

8 kW

Voltage

400 V / 50 Hz

Amperage

16 A

Length

1033 mm

Width

796 mm

Height

1738 / 1821 / 2036 / 2136 mm

Weight

1200 Kg